8:30 AM - 6:00 PM

- CNC Machines

- Apps

- Support

- Company

- Contact

- Blog

8:30 AM - 6:00 PM

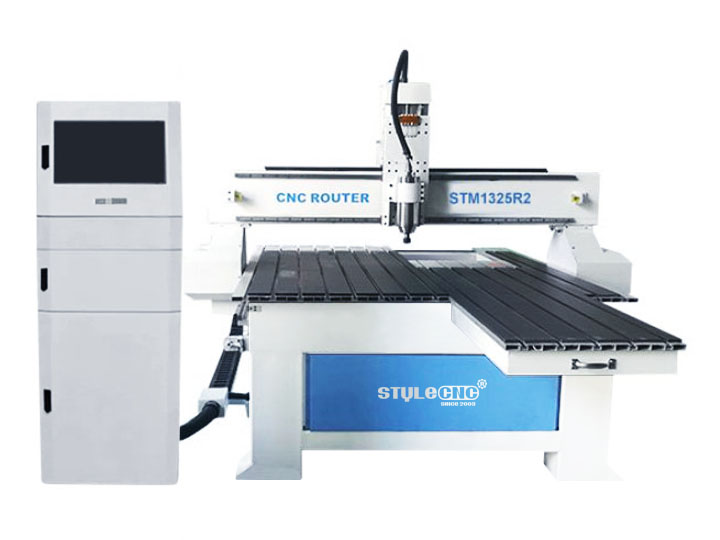

Multifunctional CNC wood cutting machine with 4th axis rotary table is designed for multipurpose woodworking plans and DIY woodworking projects. Now the cheap CNC wood cutting machine for sale at cost price.

Multifunctional CNC Wood Cutting Machine Features

1. The lathe bed adopts strong welded steel tube to avoid distortion.

2. Y axis adopts double motors to keep stable moving.

3. Z axis adopts ball screw transmission to ensure high precision machining.

4. High accuracy rack rail travel method with high speed.

5. HIWIN square guide rail with high accuracy and heavy burthen.

6. Advanced international technology vacuum with double cavity.

7. Humanization design of lathe bed vacuum and easy working.

8. Intelligent protecting working fable.

9. The rotary device can do 3D woodworking on cylinders.

Multifunctional CNC Wood Cutting Machine Details

The table is flexible to take off when need to work on rotary cutting.

The diameter of 4th rotary axis is from 80mm to 300mm, and the length is same as table size.

3KW water cooling spindle.

Independent driver for 4th axis rotary table, more easy to switch from table working to rotary cutting.

Fuling inverter.

Multifunctional CNC Wood Cutting Machine Technical Parameters

| Model | STM1325R2 |

| X,Y,Z Working Area | 1300*2500*200mm |

| Table Surface | T-sot table |

| Frame | Welded Structure |

| X, Y Structure | Rack and Pinion Drive, Hiwin Rail Linear Bearings |

| Z Structure | Hiwin Rail Linear Bearings and Ball Screw |

| Max. Power Consumption | (Without Spindle) 2.5kw~3Kw |

| Max. Rapid Travel Rate | 33000mm/min |

| Max. Working Speed | 25000mm/min |

| Spindle Power | 3KW water cooling spindle |

| Spindle Speed | 0-24000RPM |

| Stepper Driver | Stepper driver |

| Stepper Motor | Stepper motor |

| Working Voltage | AC380V/50/60Hz,3PH (Option: 220V) |

| Command Language | G Code |

| Operating System | DSP/ Mach3/ Nc-studio |

| Computer Interface | USB |

| Flash Memory | 128M (U Disk) |

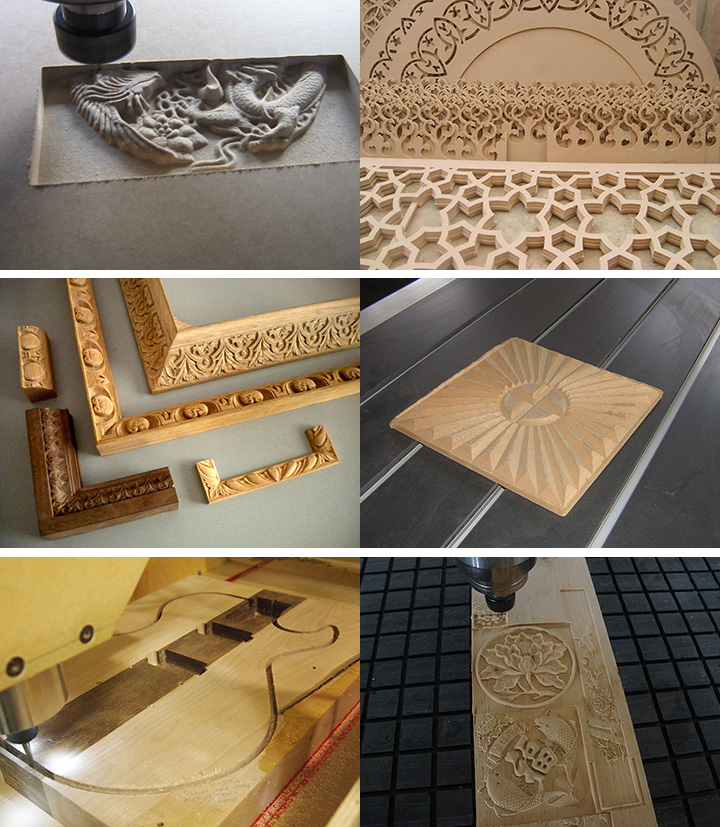

Multipurpose CNC Wood Cutting Machine Applications

1. Furniture Making: Wooden doors, cabinets, plate, office and wood furniture, tables, chair, doors and windows.

2. Woodworking: Voice box, game cabinets, computer tables, sewing machines table, instruments.

3. Plate Processing: Insulation part, plastic chemical components, PCB, inner body of car, bowling tracks, stairs, anti bate board, epoxy resin, ABS, PP, PE and other carbon mixed compounds.

4. Decorations: Acrylic, PVC, MDF, artificial stone, organic glass, plastic and soft metals such as copper, aluminum plate engraving and milling process.

Multifunctional CNC Wood Cutting Machine for Multipurpose Woodworking Projects

The router itself is of fairly high quality, you can see where they made compromises, and that in of itself is acceptable because a similar machine in North America goes for more than 20,000 USD. There is always a trade off, and knowing upfront that a compromise is made in one place or another upfront is important. The mechanicals, stepper motors, rails and drive systems all look great, I had my friends who are machinists go over the mechanicals of the machine top to bottom and they couldnt find a technical fault so far.

This CNC arrived without any damage or parts shortage. Got the assembly done within 50 minutes. The software is easy to use with the fully explained instructions.

Easy to setup, even though it takes about one hour to put together. The instructions are very easy to follow with a short learning curve. I use this CNC machine all the time to cut out MDF projects as well as solid wood.