8:30 AM - 6:00 PM

- CNC Machines

- Apps

- Support

- Company

- Contact

- Blog

8:30 AM - 6:00 PM

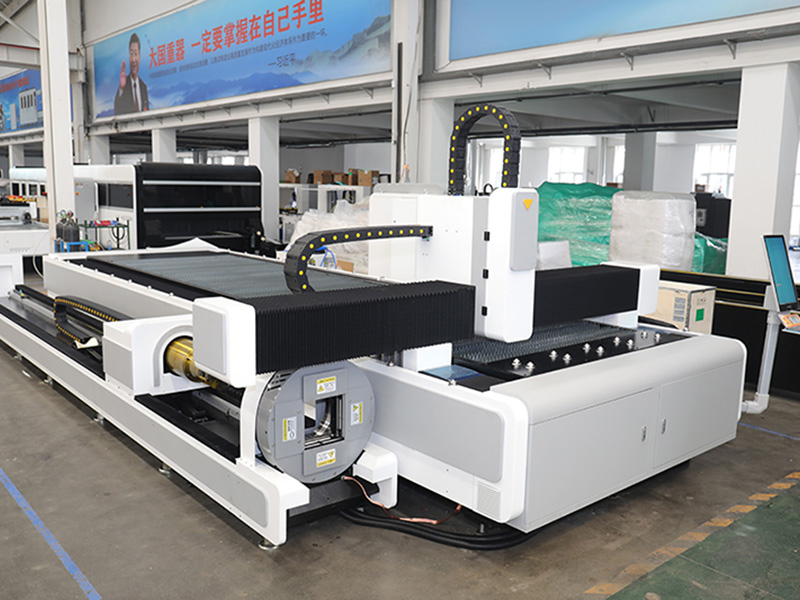

20000W ultra high-power fiber laser cutter is an automatic CNC laser metal cutting machine with power options from 1000W to 60000W, which can cut through thicker metal sheets and plates from 1mm to 120mm, as well as cut out personalized shapes & outlines from metal tubing. It's professional for commercial use and industrial manufacturing.

☑ ST-FC6025CR CNC fiber laser cutting machine combines pipe cutting and metal plate cutting processes to save costs and space.

☑ ST-FC6025CR allows you to easily obtain clean and smooth cutting edges and quality.

☑ The 6-meter-long cutting table allows you to easily handle most sheet metals.

☑ ST-FC6025CR can easily cut reflective metal materials such as aluminum, copper and brass.

☑ ST-FC6025CR can be used to cut pipes of different diameters and lengths from 20mm to 240mm.

☑ Extremely low maintenance costs saving labor costs.

☑ The service life exceeds 100,000 working hours.

☑ ST-FC6025CR comes with a CNC controller to drive the machine. The software is user-friendly and easy to operate. Beginners with no experience can easily get started.

☑ High-precision metal cutting with repeatable positioning accuracy of 0.02mm.

☑ High speed metal cutting up to 120 meters per minute.

☑ Dieless cutting, no waste of metal, saving material costs.

☑ Low cost of wearing parts. The only parts that require long-term replacement are the nozzle, ceramic and protective glass, with no other consumable costs.

| Model | ST-FC6025CR |

| Brand | STYLECNC |

| Cutting Table Size | 2500*6000mm, 1500*6000mm for choose |

| Tube Cutting Dimension | 20mm-240mm diameter, 6000mm length |

| Laser Power | 20000W (1000W, 1500W, 2000W, 3000W, 4000W, 6000W, 10000W, 12000W, 15000W, 30000W, 40000W, 60000W for Option) |

| Laser Source | Raycus (IPG, MAX, RECI for Option) |

| Laser Type | Fiber Laser |

| Max Cutting Speed | 120m/min |

| Repeated Positioning Accuracy | 0.02mm |

| Max Acceleration | 1.0G |

| Voltage | 380V/3PH or 220V/3PH |

| Machine Weight | 7500KG |

| Warranty Time | 3 years |

| Machine Size | 8870*4720*2300mm |

| Price Range | $120,000.00 - $300,000.00 |

⇲ The high-rigidity cutting table is segmented and welded, and adopts exclusive high-temperature CNC resistance furnace annealing treatment to ensure long-term stable operation of the machine.

⇲ Neatly sawtooth workbench makes cutting easier.

⇲ Pneumatic rotating device, freely adjustable speed.

The rotary device with 3pcs big torque servo motor, it provide strong power for tube turning. Both end with pneumatic chuck and rack pinion transmission,keep high accuracy.

⇲ Featuring a roller feed system, heavy cuts can be loaded with ease.

⇲ Swiss RAYTOOLS laser head with automatic focus height follower to ensure a constant distance between the cutting head and the cutting material.

⇲ ST-FC6025CR comes with professional Cypcut CNC controller system and user-friendly cutting software.

ST-FC6025CR works with files in DXF or AI format. You can also use this software to draw graphics and cut directly. Software with fly cutting mode can cut the same design to save time. It features with nesting function and can be assembled independently, saving materials and space.

⇲ The fiber laser source of China's best brand Raycus or the world's top brand IPG is optional, with a lifespan of up to 100,000 hours.

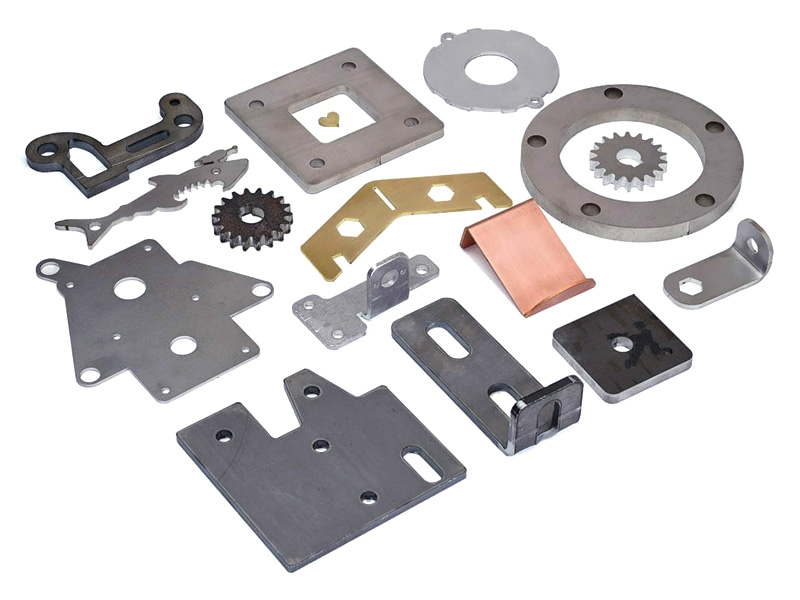

Applicable Industries

ST-FC6025CR is used in aerospace technology, aircraft manufacturing, rocket manufacturing, robot manufacturing, elevator manufacturing, ship manufacturing, sheet metal cutting, kitchen furniture, electronic components, automotive parts, cooling, ventilation pipes, signs, metal and other metal parts processing industry.

Applicable Materials

ST-FC6025CR is used for cutting carbon steel, silicon steel, stainless steel, aluminum alloy, titanium alloy, galvanized steel sheet, pickling board, aluminum zinc plate, copper and many kinds of metal materials cutting.

⇲ Strong water resit bottom in plywood.

⇲ Laser source (separated plywood case) and spare parts on the laser bed.

⇲ Corner protect by foam and fixed by protective film.

⇲ All covered by strong and hard protective film.

⇲ Vacuum packing.

⇲ Inside steel frame protector.

⇲ Plywood packing and steel strip outside fixed the box.

⇲ Finishing packing by normal container or frame container.

Free Sample Cutting Service

For free sample cutting/testing, please send us your CAD file (.plt or .ai), we will do cutting in our factory and make video to show you the cutting process and result, or send samples to you to check the cutting quality.

Progressing Solution Design

According to customer’s product processing requirement, we can design the unique solution that supports higher manufacturing efficiency and better processing quality for customer.

Customized Machine Design

According to customer's application, we may revise our machine according to customer's convenience and high production efficiency.

⇲ We will supply the laser machine with training video and user's manual in English for installing, operation, maintenance and trouble-shooting, and shall give technical guide by remote,such as TeamViewer, E-mail, Phone, WhatsApp, Skype, 24/7 online chat, and so on, when you meet some problem of installation, operation or adjusting. (Recommended)

⇲ You can come to our laser machine factory for training.We will offer professional guidance. Direct and effective face-to-face training. Here we have assembled equipment, all sorts of tools and testing facility. Training Time: 3-5 days (Recommended)

⇲ Our engineer will do a door-to-door instruction training service at your local site. We need your help to deal with the visa formality, prepaid traveling expenses and accommodation to us during the business trip and service period before their dispatch. It's better to arrange a translator (if no English-speaking) for our engineers during the training period.

⇲ 3 years for the whole machine, laser device 18 months, chiller 12 months, lens, mirror and nozzle without warranty.

⇲ Long life-time maintenance, after-sale department will offer 24/7 English online support.

⇲ Except the damage artificially, we are responsible for offering the fittings free of charge during warranty.

⇲ After the warranty period expired, the buyer only need to pay the actual maintenance cost.

⇲ Certificate support: CE, FDA, SGS.

I was wary of purchasing a Chinese-made laser cutter off the internet, but the reviews convinced me to give it a try. Got this unit in 28 days. No trouble in assembly and parameter setting. Ive tried it to cut 304 and 316 stainless steel plates and pipes for kitchenware and gotten the cleanest cuts. Its a powerful all-in-one machine for both sheet metals and tubes. No regrets with the buying of this great cutter.

I already have a CNC plasma machine, but I was always want to purchase a fiber laser cutter as a update. This machine has not let me down at all. Perfect cutting speed and smooth cutting edge deserve a 5 star.